EVI Ski: Slide into the future on long-lasting upgradeable skis

By Åsa H. Aaberge

After a decade of experience handcrafting skis desgined for the future, the team behind EVI Ski has launched a project that comes full circle, back to the beginning.

The founder of EVI Ski, industrial designer Endre Hals, started out with an idea to develop a set of skis that was designed for longevity, but could be continually upgraded after years of wear and tear. Inspired by his own love for skiing, Hals looked to Japanese manufacturing traditions and the broad material aspects of skis to design a model that can last forever.

Evi founder Endre Hals skiing on Evi skis behind the factory. Photo: Evi Ski

Hals’ vision of longevity is in the name EVI, pronounced ‘evig’, which means ‘forever’ in Norwegian. But the original meaning behind EVI is the idea of ‘evolving industries’ – a notion that Norwegian ski manufacturers continuously aim to integrate into their products.

Endre Hals, founder of Evi Ski. Photo: Rikke Løe Hovdal

Designed for longevity

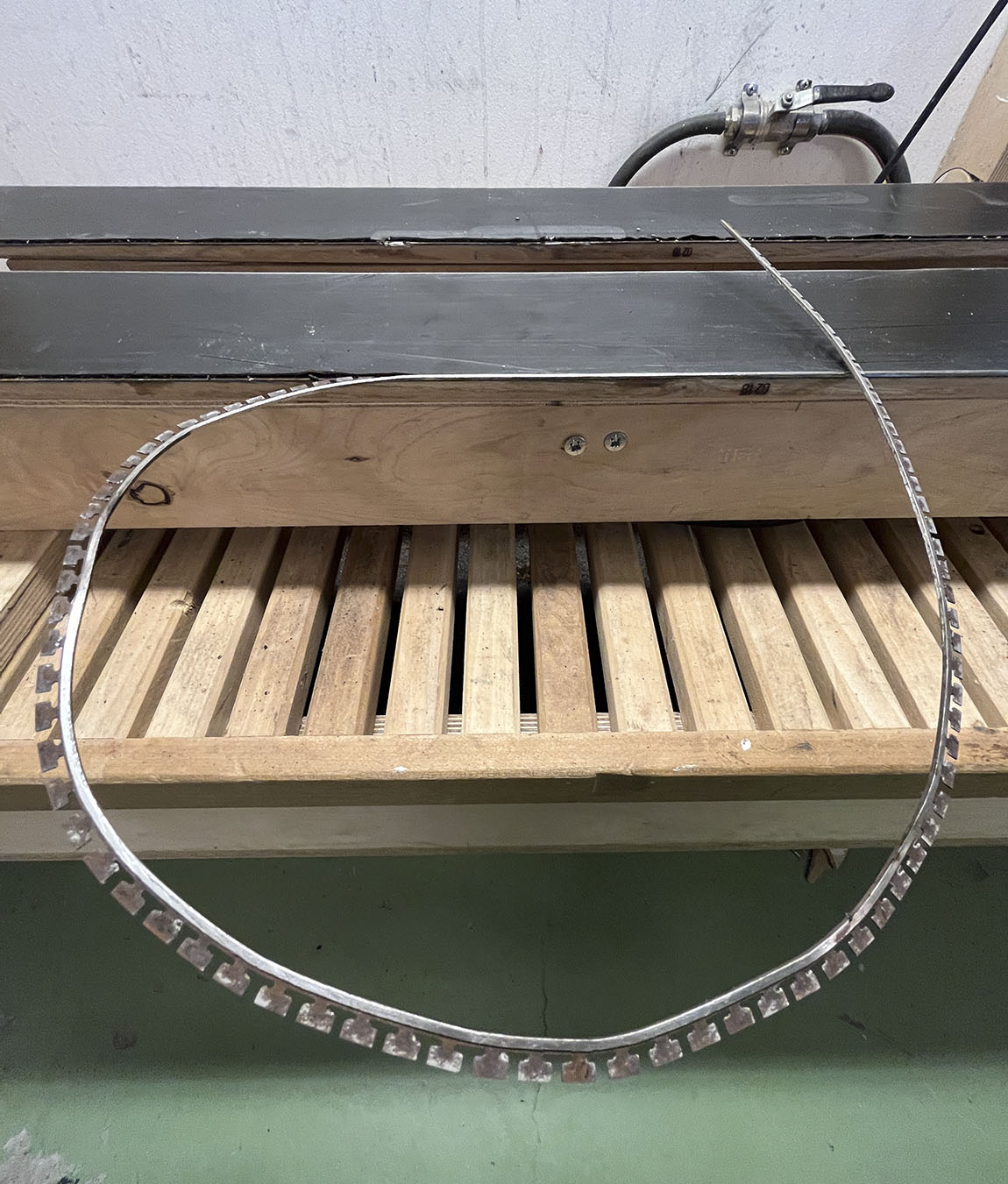

“The thought behind EVI is to make a ski with a core so well-reinforced that it allows for full upgrades and repairs. This winter, we are launching Repressed, a concept where we give worn and torn EVI skis a new and prolonged life,” explains Hals.

Evi in the making. Photos: Martin I. Dalen

While studying industrial design, Hals experienced an enormous focus on mass production and a general tendency to strive for profit. Industrial design students were taught that they should not aim to make products in Norway, “merely design here and produce abroad,” Hals says. “The focus was on the notion that products should sell as opposed to last.”

EVI Ski started as a counter to mass production and fast-paced consumerism. The brand’s mission is to invest in each part of the product, preserve history and create skis for the future, whilst maintaining a sustainable focus and a low production rate.

Evi in the making. Photos: Martin I. Dalen

Small-production, bespoke models

“It all started as a rebellion. When I studied, the glorification of globalism was at its peak. But in the past, Norway was amongst the first and foremost ski-producing countries. In the early 2000s, there were next to no producers left. We design skis with a purpose,” says Hals.

The core of the ski is the core of Evi. About half of the total cost of an Evi ski is in its wooden core. “When we make improvements and adjustments to an old ski, the moulded core is still intact. Under the brand Repressed, we reproduce, skin and repress the ski, add new graphics and outer materials, but the wooden core remains,” explains Hals.

The factory is in the old barn at the farm. Photo: Rikke Løe Hovdal

Behind EVI and Repressed is a team of four located in Oppdal, a mountainous municipality in the middle of Norway. Apart from producing made-to-order skis, EVI makes a small number of skis for the Norwegian outdoor brand Norrøna. Limited stock is also carried at the local sports store, but overall, EVI skis are made solely on demand.

“For us, being directly involved in making the skis, and working on a made-to-order basis are essential to maintaining sustainable production,” says Hals.

He emphasises that keeping a limited production allows them to maintain organic and consistent company growth. “Our goal is to make skis that will slide on snow – not skis that live in storage. After ten years in business, only a handful of our skis have been produced without a specific customer,” says Hals.

Repressed ski from old Evi ski. Photo: Endre Hals

Being an organic, functional product, EVI skis feature a simple design. However, Hals also leaves room for subtle aesthetic aspects and creativity. Some skis feature helpful graphics with information ranging from how to do an avalanche search, to first aid for a broken leg, or in case of a heart attack.

“We focus mostly on clean designs with only a logo and monochromatic expression. I generally think the cleaner the look, the broader the audience. But we also do custom design, where customers request certain looks and ideas or tailored skis,” says Hals.

Repressed ski from old Evi ski. Photo: Endre Hals

Community-building in a local ski hotspot

The area of Oppdal, where the ski factory is located in a barn on the Lønset farm, is renowned for pristine skiing conditions. The climate is stable, the winters are cold and long, and the snow falls in heaps. Other than assembling future-proof skis, the EVI team also aims to be part of community-building in the local area.

“Oppdal is a paradise for free skiing. The area is returning to its former glory with new ski lifts and establishments popping up. We hope to be part of establishing a future-orientated industry and creating jobs for people living here. To have a strong position in the local community and help to draw people here is important to us,” says Hals, and elaborates. “We also work by utilising more waste material from local and regional industries. The fact that we are a small company means we can develop and discover new techniques with less harmful side effects,” says Hals. Indeed, EVI is currently using waste from the advertising industry and carbon from reclaimed windmill blades in their production.

Photo: Endre Hals

“Our goal is to make the old barn, where our factory is, a destination for visitors to see and learn how we work. To stay true to our values, be close to nature and build and pass knowledge is more important than making the best ski in the world. Our first client was from Japan, and we have had requests from retailers in the US. That is great, but most importantly, we want to stay where we are: local and sustainable,” says Hals.

In action in the area behind the factory. Photo: Evi Ski

Web: www.eviski.com Instagram: @repressedskis Instagram: @eviskis Instagram: @progskis

Subscribe to Our Newsletter

Receive our monthly newsletter by email